Articoli tecnici

Tracciare i livelli delle scorte nei processi di assemblaggio e logistica

Con un sistema wireless di requisizione automatica dei materiali, il flusso dei materiali diventa trasparente, anche per i pezzi non gestiti a magazzino. Il sistema nexy di steute è ideale per questo scopo. Al LogiMAT, il produttore mostrerà come l'ultima versione di nexy possa svolgere anche altri compiti.

Pubblicato su: IT&Production (02/2025)

Fino all'ultimo metro – Requisizione di materiale in una rete Wireless

Come si possono integrare i sistemi di veicoli a guida automatica (AGV) in una visualizzazione digitale del flusso di materiali, anche con parti non gestite a magazzino e persino con AGV di produttori diversi? La risposta è un sistema di richiesta di materiale automatizzato senza fili.

Pubblicato su: f+h (01/2025)

Monitoraggio del flusso di materiali in tempo reale

Un sistema basato sul wireless facilita la richiesta automatica di materiale senza interruzioni e può anche integrare il trasporto mobile, come AGV e carrelli. Questa opzione è preferita, ad esempio, dall'industria automobilistica o dai produttori di elettrodomestici. Le applicazioni preconfigurate semplificano l'integrazione nelle infrastrutture IT esistenti e sono attualmente disponibili sia nuovi sensori (wireless) che nuove funzioni, compresa per la prima volta una soluzione “in loco”.

Pubblicato su: dhf Intralogistik (8/2024)

Richiesta automatica di materiale in una rete wireless - Trasferimento di dati a distanza per un flusso di materiali basato sulle esigenze

Uno “specialista” tra i sistemi wireless controlla il flusso di materiali nelle aree di assemblaggio industriale, con notevoli vantaggi in termini di efficienza e costi per gli utenti. Il sistema nexy di steute, basato sul wireless, può essere integrato perfettamente nell'IT aziendale (ERP, MES) e, come strategia di piattaforma, utilizzato non solo come canale di comunicazione per un sistema automatizzato di richiesta di materiali, ma anche per altri compiti.

Pubblicato su: NET (03/2024)

Scambio di segnali multifunzionali - La rete wireless migliora la fornitura di materiali nelle sale assemblee

Il flusso delle informazioni prima del flusso dei materiali: questo è un vecchio principio stabilito ad es. Sistemi ERP e di gestione del magazzino. La pratica ha tuttavia dimostrato che anche con questo principio possono ancora esserci lacune nell’approvvigionamento dei materiali, soprattutto nella produzione di varianti. In questi casi può essere d’aiuto un sistema di richiesta senza fili, che può anche svolgere compiti aggiuntivi.

Pubblicato su: MY FACTORY (03/2024)

steute amplia il sistema di raccolta dei materiali - Stock di montaggio tracciato fino all'ultimo pezzo

Con i sistemi di requisizione dei materiali basati sul wireless, gli operatori possono avere una visione d'insieme di tutti gli articoli della loro produzione, anche di quelli che non sono gestiti a magazzino. Al LogiMAT, steute presenta l'ultima generazione del suo sistema nexy.

Pubblicato su: IT&Production (02/2024)

Sistemi automatizzati di requisizione dei materiali - I sensori wireless gestiscono i rifornimenti fino all'“ultimo metro”

I sensori che comunicano tramite controllo remoto presentano notevoli vantaggi, soprattutto nel campo dell'intralogistica. Possono essere utilizzati ovunque, ad esempio per seguire i vettori di carico nel loro percorso dal magazzino al luogo in cui il materiale deve essere assemblato. I rifornimenti sono quindi basati sulle necessità. Si tratta di una buona base per un sistema di requisizione automatizzato, in grado di svolgere anche altri compiti in officina.

Pubblicato su: Technische Logistik (03/2024)

Il wireless in vantaggio - Richiesta materiale automatizzata nell'area produttiva

Per molto tempo, le reti wireless hanno avuto una cattiva reputazione nel settore manufatturiero in termini di affidabilità. Ma la tendenza verso una produzione (di serie) flessibile, ad esempio nell'assemblaggio di automobili, ha portato a una loro crescente integrazione nelle strutture di comunicazione. Sono preferiti i protocolli wireless sviluppati appositamente per tali applicazioni.

Pubblicato su: SPS-Magazin (2/2023)

Piu' contenitori, grazie! Rete wireless versatile per l'intralogistica

La soluzione migliore per una gestione precisa delle richieste di materiale nelle aree di assemblaggio e produzione è una rete wireless che tenga occhi e orecchie aperti - in senso figurato - e sappia in ogni momento dove si trovano i rifornimenti. In questo modo viene garantito il rifornimento di tutte le stazioni di assemblaggio, senza carenze, durante l'intero processo.

Pubblicato su: MY FACTORY (10/2023)

Gestione precisa delle richieste di rifornimento in intralogistica – Una rete wireless universale come piattaforma

"In un colpo solo" – è il modo più semplice per descrivere i diversi modi di utilizzare una rete wireless per la gestione delle richieste di rifornimento. La rete nexy assume molteplici funzioni e permette il controllo preciso del flusso del materiale in produzione, assemblaggio e spedizione.

Pubblicato su: f+h Fördern und Heben (09/2023)

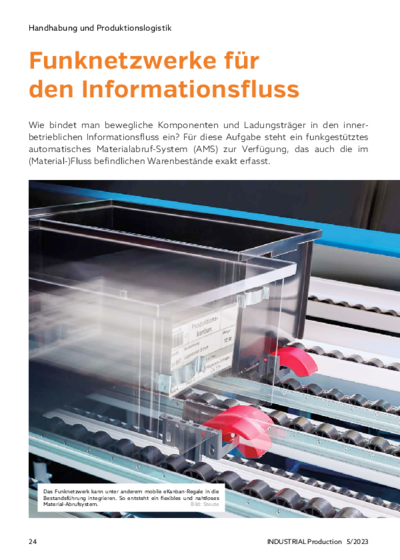

Reti wireless per il flusso di informazioni

Come integrare i componenti mobili e i supporti di carico nel flusso informativo aziendale? Proprio per questo compito è disponibile un sistema automatizzato di richiesta materiale basato sul wireless, che monitora le scorte con precisione in qualsiasi punto del flusso (di materiale).

Pubblicato su: INDUSTRIAL Production (5/2023)

Rifornimento via wireless - Integrazione di AGV, dolly e scaffali eKanban

Perché è necessario un sistema di richiesta automatizzato, se già si dispone di un ERP o WMS? Buona domanda. E' necessario se i livelli delle scorte devono essere gestiti non in modo approssimativo, ma in modo preciso.

Pubblicato su: Technische Logistik (04/2023)