Technical articles

Multifunctional signal exchange - Wireless network improves material supplies in assembly halls

Information flow before material flow: this is an old principle established for e.g. ERP and warehouse management systems. Practice has shown, however, that even with this principle there can still be gaps in the material supply – especially in the manufacture of variants. A wireless-based requisition system can help in such cases, and can also assume additional tasks.

Source: MY FACTORY (03/2024)

Automated material requisition systems - Wireless sensors manage replenishments to the "last metre"

Sensors which communicate by remote control have considerable advantages, especially in the field of intralogistics. They can be used anywhere, for example to track load carriers on their way from the warehouse to wherever the material is to be assembled. Replenishments are then needs-based. This is a good basis for an automated requisition system, which is also able to assume other tasks on the shop floor.

Source: Technische Logistik (03/2024)

Wireless has the advantage - Automated material requisition on the shop floor

For a long time, wireless networks had a bad reputation in factories regarding their reliability. But the trend towards flexible (serial) production, e.g. in car assembly plants, has led to them increasingly being integrated in communication structures. Wireless protocols developed specifically for such applications are favoured.

Source: SPS-Magazin (2/2023)

More containers, please! Versatile wireless network for intralogistics

The best solution for precise management of material requisition in assembly and production halls is a wireless network which keeps its eyes and ears open – so to speak – and knows where replenishments are located at all times. This guarantees that all assembly points are kept supplied – without shortfalls, across the entire process.

Source: MY FACTORY (10/2023)

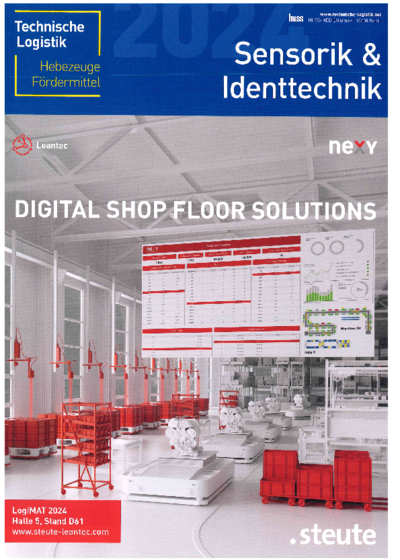

Precision requisition management in intralogistics – Universal wireless network as a platform

"At one fell swoop" – this is the simplest way to describe the different ways of using a wireless network for requisition management. The nexy network assumes multiple functions and facilitates precise control of material flow in production, assembly and consignment.

Source: f+h Fördern und Heben (09/2023)

Wireless networks for information flow

How are moving components and load carriers to be integrated in the company information flow? A wireless-based automated material requisition system is available for just this task and monitors stock precisely anywhere within the (material) flow.

Source: INDUSTRIAL Production (5/2023)

Remote supply replenishment - Integration of AGV, dollies and eKanban racks

Why is an automated requisition system necessary if you already have an ERP or WMS? A good question. It is necessary if stock levels are to be managed not approximately, but precisely.

Source: Technische Logistik (04/2023)

Closing the gap in the information flow - Live monitoring of material flow with wireless network

Farewell to the conveyor belt: under this motto, multiple forward-thinking companies have reorganised their material flow. Stationary conveyors have been replaced by mobile and thus flexible units, such as AGV, tugger trains or mobile eKanban racks. The prerequisite for such advances is a new approach to information flow – and the logical way to solve this is wireless technology.

Source: robotik UND PRODUKTION (02/2023)

The wireless backbone supporting communication

When automating intralogistics, the guiding principle has to be: information flow before material flow – the latter always being mobile. With a wireless network, processes are represented comprehensively and precisely at all times.

Source: konstruktionspraxis (04/2023)

Transparency down to the last metre

MATERIAL FLOW – At Volkswagen in Dresden, "transparent manufacturing" is completely real, as more and more production companies now realise the principle of complete transparency, at least at the level of material flow. A wireless automated material requisition system closes the (information) gap down to the last metre.

Source: GO>>ing (03/2023)

Sensors and antennas are best when integrated

In a project by the cluster of excellence it´s OWL, steute is currently testing the integration of sensors and antennas in the enclosures of control systems and user interfaces for industrial, as well as medical applications. A combination of laser-direct structuring and additive manufacturing is being used. The results are extremely promising.

Source: etz (11/2022)

Stock monitoring: remote materials requisition for efficient intralogistics

Uninterrupted monitoring of stock within the in-house material flow is a prerequisite if replenishments are to be needs-based. The usual enterprise resource planning (ERP) systems have some gaps which can be closed by opting for a remote automated materials requisition system.

Source: FUTURE MANUFACTURING (10/2022)